The Roveras age their briar in the "briar bank," located in the house's attic. Here, thousands of briar blocks are stored in burlap bags that are tagged and dated. When the briar is ready for use, it's brought down to the workshop, where it's placed on shelves atop a workbench. Most of Ardor's briar comes from Tuscany and Sardinia, though the Roveras are experimenting with briar from Liguria.

Angelo Rovera's workbench remains untouched since his death in 1999

"Briar from Tuscany and Sardinia is very nice because it has a naturally light color that's easy to stain," Damiano comments. "We only use Ligurian briar occasionally because, while it produces a light color, it typically produces more flaws. Pipes made from Ligurian briar are often sandblasted or rusticated."

Damiano buys directly from the wood cutters to improve the quality of the briar he purchased, and the family believes that it has stockpiled enough excellent-quality briar to make top-grade pipes for many years to come.

"Buying directly from the suppliers gives me excellent results and I throw away fewer blocks, but it's so expensive," he says. "Because we're not a very big pipe company, it's important for us to get the best results that we can."

Damiano estimates that Ardor purchases between 2,000 and 2,500 briar blocks each year and has stockpiled enough excellent briar for years to come. All briar is aged for at least 10 years and approximately 20 percent has been aged for more than 15 years.

"We reserve that really old briar for our special shapes," he says. "It's a big investment but the results are good because we can offer something that's a little nicer for our customers."

While having an ample supply of seasoned briar is an important factor in Grafting a pipe, it's what Dorelio and Damiano do with the briar that makes it worth smoking. The mortise and tenon meet perfectly flush, eliminating turbulence in the smoke channel. Damiano also stresses that excellent smoking qualities are created by finding the proper proportion between the tobacco chamber and air hole so that as been the heat and smoke can be managed.

“The size of the tobacco chamber and the air hole changes with every pipe we make," he says. "Different pipes require different dimensions, :and it's up to the pipemaker to discover what the pipe needs. Our Giant pipe series might have tobacco chambers that are 27 mm or 28 mm deep, but our smallest pipes may have tobacco chambers that are 18 mm deep. Likewise, the air hole is drilled to 5.3 mm for our Giant pipes, while it varies from 3.5 mm to 4 mm for the rest of our pipes. It depends on the size of the bowl. However, the air hole is always 3 mm at the mouthpiece's lip."

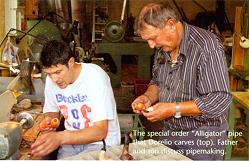

Damiano pauses as Dorelio once again brings the alligator pipe over to examine. They joke that the pipe's "eyes" should be stained red before commenting on other engineering aspects that define Ardor pipes.

"A finished pipe must have a tobacco chamber with thick enough walls to prevent burnouts," Dorelio says. "And then, the pipe must always have a head and a tail. It must have fluidity of lines that give it a soul."

Finding a pipe's soul is a challenge that Damiano admits was a struggle for him to overcome. Early in his career, he often became frustrated when a shape he tried to carve became untenable due to flaws in the briar. Then he discovered that those frustrating flaws were part of the briar's beauty and that he should allow those flaws to accentuate the pipe's beauty. Although the pipe might need to be rusticated or sandblasted, he now achieves the shape that he had in mind more often.

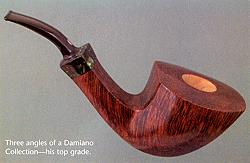

Like his father, Damiano prefers the classic shapes, though he likes to give them his own interpretation.

Dorelio adds that Damiano's apprenticeship ended once he accepted that he had to take what

the briar offered while still maintaining aesthetically pure lines.

"Sometimes you get bad results," he says. "But if you learn from these then you will become a better pipemaker. If every idea were perfect, making pipes would be too easy and creativity would remain stable because nothing would give you the willpower to research something new."

To maintain the fluidity of their pipes' designs, the Roveras hand cut every mouthpiece from acrylic or Cumberland rods. In recent years, Damiano in particular has received praise for the extra work he puts into each mouthpiece. While it costs more and practically doubles the amount of time it takes to make a pipe, Damiano says the effort is worth it.

"Every pipe needs its own mouthpiece," he comments. "We couldn't create the pipes we make without producing our own mouthpieces, and it's easier for us to do it instead of using preproduced ones. A lot of American pipe smokers told me that there aren't many pipemakers who spend so much time on the mouthpieces. Making our own mouthpieces is very important for me because it adds a good touch to the pipe's entire beauty."

Making their own mouthpieces gives the Roveras more freedom to take custom orders as well. Damiano estimates that nearly half of their annual production is custom orders. While' some customer demands are farfetched and sometimes impossible to create, others have sparked the Roveras creative energy and allowed them to see market trends.

"I always appreciate suggestions and comments from my customers," Damiano states. "Following customer suggestions and ideas presents you the opportunity to compare and add to your own ideas. You may not achieve something special without the suggestion of someone else. It's great to offer something different too. Taking special orders from customers is a good thing because it allows you to grow and develop your skills and maybe open your mind to new ideas."As an example, Damiano cites| Ardor's Giant and Fantasy series pipes,' In 2000, Ardor made a few Giant and Fantasy pipes because people wanted larger pipes or freehand pipes with different types of adornments or colors. Nine years later, those few pipes have grown into full-fledged Ardor lines with many different shapes, and the Ardor pipes are regularly adorned with different materials and use unique color schemes.

Ardor and Damiano pipes sometimes feature colored mouthpieces, which are made from special rods that Damiano custom orders from a friend. Bamboo and silver are also common adornments the Roveras use to accentuate certain pipes.

"Damiano has taught me to always look for something new," he says. "I'm much happier being a pipemaker now than I have ever been because he has helped me realize that there are many alternatives to explore when making a pipe, which leads more people to enjoy our work."

Ardor pipes were primarily sold in Europe, with a few finding their way into the United States, until 1997, when Steve Monjure bought his first Ardor pipe. A year later, Monjure visited the Rovera family. They developed a strong business relationship, and more importantly to the Roveras, a fast friendship.

"It's always important to do business with people who understand pipes," Damiano says. "Steve has helped introduce our pipes to more people in the United States than we ever could have imagined. He lets us know what American pipe smokers want, and we do our best to fill that demand. We work very well together and we collaborate on new ideas."

Some of those new ideas have already started to appear on tobacconists' shelves, while others are still being created. Damiano is experimenting with oil-curing processes in the hopes of releasing a line of oil-cured pipes. And he and his father are experimenting with unique shapes that they hope to release as a special 100th anniversary pipe series in 2011. Both men repeatedly comment on their desire to continue searching for new twists to introduce to their craft. The freedom to explore and assert his creativity led Damiano to throw away his spreadsheets and join his father in making pipes.

"I don't like to stay on the same road," Damiano states. "I like to have the possibility to use all the best ideas I can. I wanted to learn a tough job, and pipemaking requires you to have an intense desire to see your ideas through. The secret is that you can achieve good results if you spend the time."

The prodigal son has come home, where he belonged all along. P&T

See the table below describing the pipe nomenclature

(Return to the Previous Page)

(Return to the Ardor Home Page)