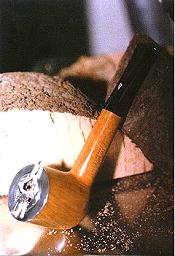

Elio looks through a pile of briar blocks, setting aside four or five before finding one he likes. He holds it up and looks carefully at the grain, then sets it on a table and draws a Dublin shape on it. "Still," he says, "it could be a different shape. The most natural way to work is when you have not decided how the pipe will be in the end." He takes it to the drill press and drills the tobacco chamber, then to the band saw and cuts the excess wood away. From there he goes to the lathe to drill out the smoke hole and mortise. He selects and puts on a stem, then moves to the sanding wheel and begins shaping the pipe. Most of the shank, though, he handshapes with files and sandpaper. He removes the stem only when he needs a better angle for shaping away from the mortise area, and quickly replaces it. It is important that the stem remain a part of the pipe throughout the shaping and finishing process.

"We have different styles for the different markets," says Guido. "Now that we are selling again in the United States, we make more medium and large pipes than before. For the Italian market, smaller pipes are more popular. Italians prefer smaller pipes-we like to keep a pipe in our mouth when we smoke." That statement seems to be true. Guido, at least, almost never takes his pipe from his mouth, except when relighting it.

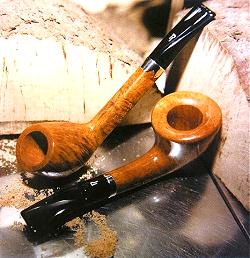

Elio stops sanding to show us the grain of the pipe he is shaping. The most important thing, he explains, is that the grain of the wood harmonize with the shape of the pipe. "We don't sell wood," he says. "We sell pipes. The successful pipe is a combination of material, style, workmanship, design, proportion-it all has to work together."

It takes an average of three hours to complete a Rinaldo pipe, and these artisans make it look easy. But they have had plenty of practice-more than 50 years of combined carving experience.

That experience started when Elio was 15 years old. Employment prospects in their native Sicily were not encouraging, so he moved to Pesaro at the urging of a friend, and began working for a major pipemaking company.

Guido, who started smoking a pipe at age 14, maintained an intense interest in his brother's experience making pipes. He was working in the jewelry-making trade, but at age 16, he joined Elio in Pesaro, and began learning to make pipes himself. Both brothers displayed a terrific aptitude for the trade, and within a few years had attained considerable responsibility for design, modeling and perfecting finishes.

Finally, in 1987, they decided to gamble on themselves and Rinaldo pipes. They had saved for this, but it wasn't quite enough. Guido sold his motorbike to buy machinery. He postponed his marriage to invest more time and money in the company. Both brothers worked tirelessly to get the shop in order and to manufacture the finest pipes possible.

The first four or five years were difficult. Name recognition was hard-won, especially given the limited number of pipes that the Rinaldos could manufacture. Only 1,200 to 1,500 pipes a year can be made under the quality guidelines that the brothers have set for themselves. "We don't want to make more than that," says Guido. "The main driving force for us is the needs of the smoker. We cannot make more pipes and still maintain the quality we believe the smoker deserves."

The pipe that Elio has been working on is nearing completion. After considerable hand-sanding, the stain is applied. This pipe will have a silver band, too. This is one of the remarkable aspects of Rinaldo pipes: The silver work is done on premises, not with manufactured bands, but with a silver fusion technique that Guido has perfected. His experience making jewelry is a valuable crossover skill for Rinaldo pipes. He fuses pure silver with copper, making a silver bar that is 80 percent pure, then puts it in a acid bath, after which it is polished. From that point, it can be drawn into a silver wire in a special machine, then hammered or shaped in any way he wishes. Many impressive silver designs have been applied to Rinaldo pipes, all completed from scratch in the shop. Once the silver is applied to Elio's pipe, it is finished.

The only process completed outside the shop is the sandblasting. It is still done by the Rinaldos, but with a sandblasting chamber located off premises. This, too, is an integral part of the pipe, once it is decided that sandblasting will enhance the final product.

Elio pulls a tray of finished pipes from a drawer under a workbench. "Each one," he says, "is a combination of many things, all working together. The big secret to pipemaking is time. There will always be briar. But time is a valuable thing. There is less time in the world than anything else. But our pipes reflect our willingness to invest that precious thing."

"No one aspect of a pipe can distinguish it," says Guido. "It is not just a nice sandblast. It is not just nice grain. It is not just a good shape. No, it

is the blast and the shape and the coloring and the design and the finishing process and everything else that makes a pipe what it is. Every part must work

with every other part. Few pipemakers can say that the whole pipe is beatiful." With Rinaldo pipes, the whole is definitely greater than the sum of its parts.

For the name of a retailer near you carrying Rinaldo pipes, or for additional information, contact Monjure International, 204 Shadowlawn Drive, Jamestown, NC 27282-9623; telephone 336.889.2390, fax 336.889.9437.

(Click Here to Return to the Previous Page)

Rinaldo Finishes:

Lithos - Rustic (Black/Brown/Tan)

Sahara - Sandblast (Black/Brown/Tan)

Triade - Smooth (Walnut)

Y

YY

YYY

YYYY

Fiammata

Collection (available in all finishes)

(Note: Lithos/Sahara Finishes are available in Grades Y/YY/YYY: Triade Finish is available in Y/YY/YYY/YYYY. All Rinaldo shapes are available in the regular bowl size and the Titania (stamped "T") which is a bowl of greater dimensions.

Briar Line - (Briar ring on shank)

Silver Line - (Silver ring on shank)

Gold Line - (Gold ring on shank)